Coarse Limestone Using Crushing Plant

Limestone Aggregates Processing SHANGHAI SANME

2024年10月25日 The Limestone sand making process is divided into four stages: coarse crushing, medium fine crushing, sand making and screening The first stage: coarse crushing The pebbles blasted from the mountain is fed uniformly by the vibrating feeder through the silo and 2021年6月24日 Trackmounted crushing plants – fully mobile jaw, cone or impact crushing plants, with or without screens, and equipped with open or closed circuit and discharge Crushing and Screening Handbook AusIMM2018年9月15日 Limestone is a sedimentary rock composed primarily of calcium carbonate with the occasional presence of magnesium Most limestone is biochemical in origin meaning the Limestone Quarrying and Processing: A LifeCycle 4 天之前 The limestone aggregates crushing generally has four steps: coarse crushing, sencondary crushing, sand making and screeningLimestone Aggregate Crushing JXSC Machine

.jpg)

New insights into double roll crushing ScienceDirect

2023年11月1日 In coarse comminution, double roll crushers (DRC) are used for the size reduction of blasted materials and in secondary comminution In the primary crushing stage, 2024年9月24日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and Crushing Plant Design and Layout Considerations 911 2023年7月24日 Coarse Crushing The raw materials will be sent evenly through vibrating feeder from the bin to the jaw crusher for coarse crushing The crushed materials together with the Limestone Processing Plant Luoyang Dahua2024年10月8日 Mobile limestone crushing plant has emerged as efficient solutions for processing limestone in various settings, particularly in remote locations and smaller projects Mobile Limestone Crushing PlantSBM Industrial Technology

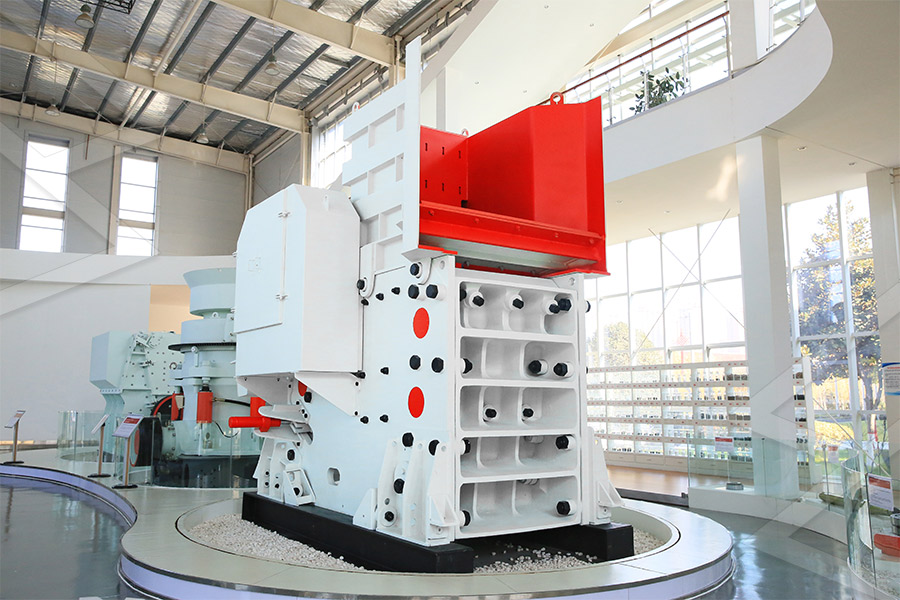

Limestone Crushing Solution Eastman Rock

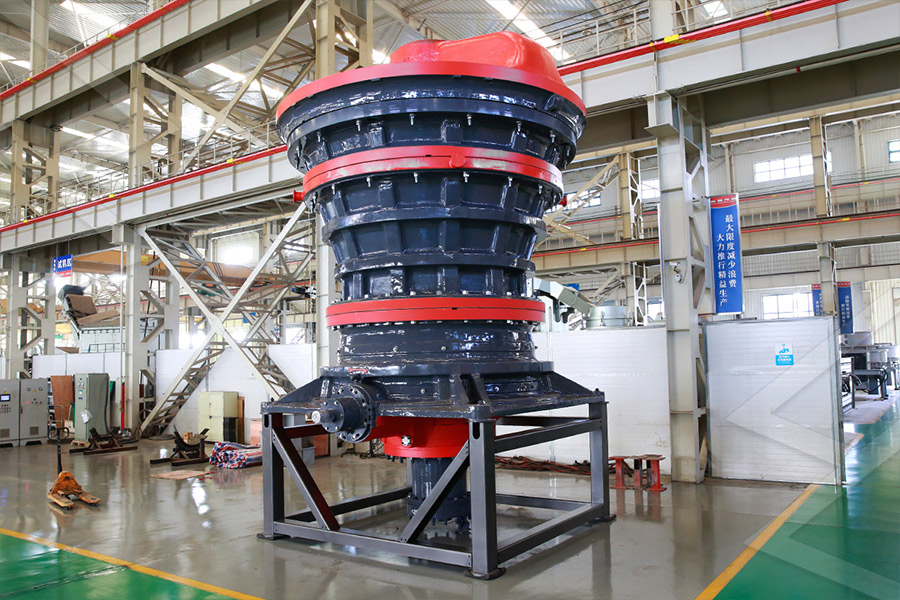

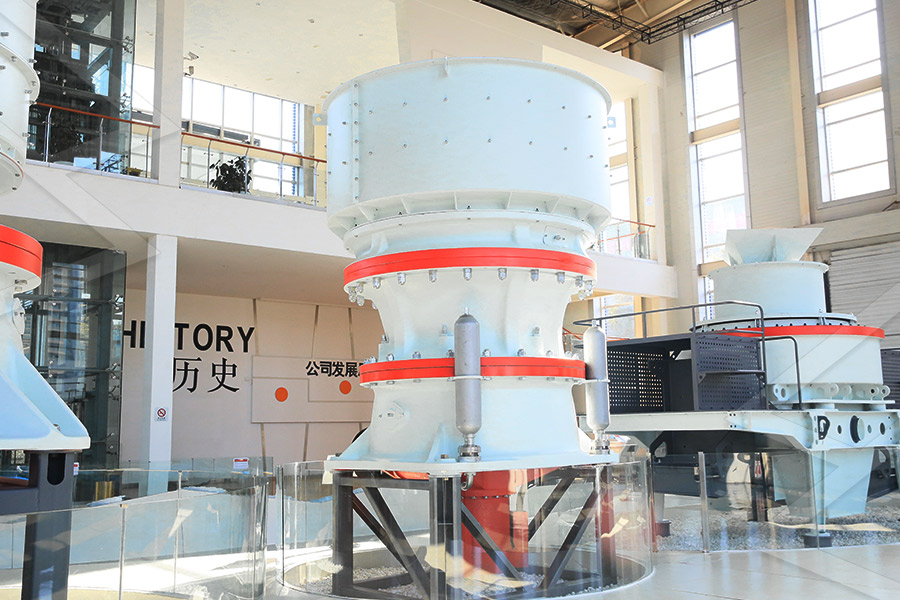

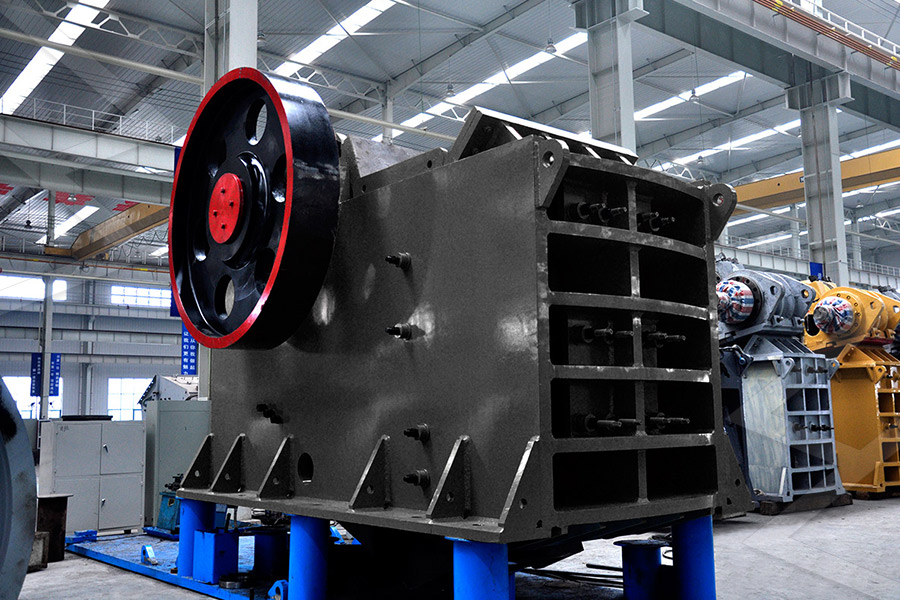

Introduce how to crush limestone, whole limestone crushing plant flow layout (with photo), and related rock crusher machine Contact us to do free flow design2024年10月25日 Limestone medium crushing equipment recommended: impact crusher cone crusher The impact crusher can granite, limestone, concrete, and the like coarse materials with a side length of less than 500 mm and a Limestone Crushing Plant Layout and Price2024年6月18日 The aggregate crushing plant design should be tailored to different production requirements (raw material, capacity, and output size) Primary crushing The raw aggregate is first fed by a vibrating feeder and 5 Steps to Build a Profitable Aggregate 2018年11月14日 limestone crushing plants The main features are as follows: (1) Being light in weight, both transportation and assemblage are easily single toggle crusher can render both "coarse and medium" crushing and "medium and fine" crushing 신형 FSK 죠 크러셔의 CRUSHING PLANT SAND PLANT MILL PLANT

.jpg)

What Machines Do Stone Crushing Plants Need?

2024年10月14日 Explore 11 essential machines required for a stone crushing plant Learn about their working principles, applications, and advantages Essential in a cement plant Can crush limestone, gypsum, and concrete 2020年1月22日 In this paper, the role of crushing operation on the cubical controlling features of coarse aggregates, and its influence on the shape distribution characteristics of aggregates (ie angularity Investigation on the morphological and mineralogical properties of 2017年9月1日 New granite crushing plant is designed using Bruno simulation software Among three crushing circuit, the first crushing circuit produces 48% of ballast, 17% of 25+9mm, 4% of 9+48mm, 6% of 4 (PDF) Application of Crushing Software in Aggregate Plant2024年10月6日 Dolomitic limecrushing plant or coarse limestone, known by its agricultural term “builder’s lime,” is excellent in providing magnesium, a vital plant nutrient This type of liming material is recommended when soil tests indicate a magnesium deficiency and soil acidity Thanks to its slowreleasing nature, dolomitic lime provides long The Role of Crushed Limestone In Agriculture Pontotoc

.jpg)

Crusher Plant For Sale Get Crushing Plant Price Philippines

Crusher plant for sale is mainly used for crushing coarse materials or disposing of the construction waste, thereby producing sand, aggregate, and other kinds of fine materialsCrusher plant can meet the processing requirements of river pebble, cobblestone, granite, marble, basalt, slate, quartzite, construction waste, limestone, and other hard or soft rocksAs it will be necessary to move the crusher in the future, Semen Bima has opted for a semimobile design of the crushing plant The plant capacity is 1000 t/h with a product grain size of 50 mm The detail engineering of the semimobile crushing plant is a close cooperation between our locations in Beckum, Hanoi and PuneCrushing Technologies thyssenkrupp PolysiusCrushing may be in open or closedcircuit, depending on the required product size distribution Two basic crushing flowsheets are shown in Figure 61: (a) the older style (“traditional”) 3stage crushing circuit ahead of a rod mill, and (b) the more modern opencircuit primary crushing prior to SAG milling with crushing and recycling of “critical size” material (see Chapters 5 and 7 Crushing Plant an overview ScienceDirect Topics2 天之前 Customized 300350 TPH Limestone Crushing Plant in Kazakhstan Basic requirements: The throughput capacity of the project ranges from 300 to 350 tons per hour Its out put sizes are about 05mm, 510mm, and 1030mm Limestone Crusher Machine: Boost Quarrying

Limestone Crushers Pulverizers Williams

Below you can explore our catalog of products that can complete a variety of limestone crushing applications Direct Fired Roller Mill Pulverizers Williams Direct Injection Roller Mills are used as limestone grinding machines and can 2022年4月20日 The particle size of limestone crushing is very small after coarse crushing and medium and fine crushing If sand making or grinding is required, it needs to be further processed by sand making machine or grinding Limestone crushing and grinding production line 2024年4月10日 The coarse crushed stone is then moved to the impact crusher for a fine crushing Finely crushed limestone is then transported to the vibrating screen in order to obtain different stone sizes All stones that meet granularity requirements are transported to the stockpile, using the belt conveyorLime Production Line Limestone Equipment Manufacturer2024年10月23日 K3 Series Portable Crushing Plant It uses modular vehicle design, able to be transported without disassembly granite, marble, basalt, limestone, quartzite, pebble, iron ore, copper ore, mine waste, construction waste, etc Technical Consultation Advantages Cases Material Better Feeding Capacity The coarse crushing module adopts K3 Series Portable Crushing Plant sbmchina

.jpg)

Stone Crusher Indonesia Crushing Pebbles, Basalt,

6 天之前 AIMIX offers stone crusher Indonesia for the processing of rocks, pebbles, and limestone, and secondly for mining, smelting, building materials, road, railroad, water, and chemical industries, etc Additionally, we can also provide you with a special stonecrushing plant for the processing of construction waste, which can be cleverly reused2019年3月1日 During secondary crushing, the background concentrations were achieved at a 350 m distance for coarse particles • Dust concentrations in the limestone quarry were half of that measured in quarries processing granitic rock material • Using the same setup, it was shown that crushing generates more dust and more coarse particles than drillingDust emission from crushing of hard rock aggregates2022年3月9日 This setup is a 500tph complete limestone crushing plant, the max input size is 1020mm, output sizes are 05mm, 519mm, 1925mm,2550mm It is configured with hopper, vibrating feeder DN6015, primary jaw crusher PE1200*1500, 2 sets impact crusher PF1520,4 sets vibrating screen 2YD3072, and 12 pcs belt conveyors Flowchart Explanation 1 The 500TPH Limestone Crushing Plant JXSC Machinecoarse aggregates with high crushing susceptibility The crushing resistance was evaluated by using various crushing parameters and the corresponding critical value of these parameters was Crushing Characteristics of Coarse Aggregates for

.jpg)

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日 equipments used for crushing work s one is by using crushers and other one is by using impacto rs This diagram illustrates the stages of s ize reduction from 1000mm to 4 mm 32022年8月25日 The crushing characteristics of coarse aggregates for asphalt concrete were investigated under static and dynamic aggregate crushing value tests (ACVTs)Crushing Characteristics of Coarse Aggregates for Asphalt 2024年7月11日 Limestone crushing plant process The limestone aggregate production line is divided into three stages: coarse crushing, medium and fine crushing, and screening The first stage: coarse crushing The limestone Limestone aggregate crusher plant stationary 2016年3月11日 Most crushing plants are now designed on the lines shown in Fig 1, which is a diagrammatic view of a twostage arrangement The ore from the mine is dumped in the coarse ore bin, from which an automatic feeder Crushing Plant Flowsheet DesignLayout

.jpg)

6 Types of Coal Crusher: Which Is Best for Crushing My Coal?

2023年10月8日 In addition, the entire coal processing plant must be considered to make the coal crushing plant compatible with the equipment of the screening plant, powder grinding plant, and coal wash plant, such as vibrating screens, coal mills, rotary dryers, etc The following are commonly used equipment combinations in the coal crushing plants:On top of the silos there is a screening plant witch splits the material into the fractions 01, 13, 38, and 816 mm We also have a storage building where we store 01 mm agricultural limestone, and openair storage areas for 03 mm coarse agricultural CRUSHING PLANT GK KalkFigure 2 shows an example of how the crushing plant can be divided into primary, secondary, and tertiary stages The aggregate produced in a primary crusher is classified using a screen into a 0 Threestage crushing plant Download Scientific Diagram2022年8月25日 The crushing characteristics of the aggregates are essential to ensure the stability of asphalt mixtures The crushing resistance is usually evaluated quantitatively by using an aggregate crushing value test [8] The tested aggregates are compacted and compressed in a cylinder by a plunger without lateral deformationCrushing Characteristics of Coarse Aggregates for

.jpg)

Limestone aggregates production plant 200tph Baichy

2024年8月14日 Let’s take limestone aggregates production plant for example 1 Selection of jaw crusher: Using jaw crusher PE750*1060 as primary crushing, the maximum feed size can reach 630mm After the primary crushing, the particle size of the material can be basically controlled within 130mm, preparing for the secondary crushing2023年9月2日 The relationship between the microcracks of a single particle and the crushing strength was studied by virtual experiments The threedimensional profile of a single particle was obtained by CTscanning technology The particle bonding model is used to fill the threedimensional contour to construct virtual particles, and the virtual crushing experiment is carried Study on the influence of microcracks of coarse aggregate 2021年6月24日 700mm coarse SD 285 t/m3 Abr 1227 g/t Cr 20 % 450 B13503V Load 75 % 450 Opening 100 mm 305 145 Setting 150 mm C110 68 % 26 quarry 305 305 145 92 53 397 320 Flexstroke 32 mm Portable crushing plants – excellent transportability between sites and fast installation, in addition to high crushing capacities Can be fi tted with jaw, cone Crushing and Screening Handbook AusIMM2024年9月14日 The stone crushing plant can produce sand and gravel aggregates used in construction, highways, railways, water conservancy, mining and other industries including river pebbles, limestone, construction waste, Stone Crushing Plant DASWELL

Limestone Crusher: What Is It How Does It

4 天之前 Tips For Using A Limestone Crusher Effectively 1 Precrushing Before beginning to use a limestone crusher, it’s essential to precrush the material This will help to reduce the overall size of the material, making it Belt conveyor– A belt conveyor crushing plant is a kind of mobile or permanent crushing plant that moves processed materials from one crushing stage to another using belt conveyors Belt conveyors are a crucial component of many Demystifying the Crusher Plant: A 2023年2月28日 Aggregate Crushing Plant; Limestone Crushing Plant; Granite Crushing Plant; Projects Menu Toggle 500t/h Coal Gangue Mobile Crushing Plant; 450t/h Stone Mobile Crushing Plant; 320t/h Construction Waste Material Crushing Station; 250t/h Limestone Mobile Crushing Plant; 200t/h River Gravel Mobile Crushing Plant; 200t/h Pebble Crushing Mobile Primary and Secondary Crushing: Understanding the Basics2017年5月30日 AN EXPERT IN CRUSHING NONABRASIVE MATERIALS Primary impact crushers are preferred for their high performance and high reduction ratios in crushing softer substances like gypsum and limestone Due to the different principle of crushing these materials, the reduction ratio is higher than in jaw crushers MPI1313 MPI 1515 MPI 1620CRUSHING SCREENING Crushing and Screening

Limestone Crushing Plant MadeinChina

China Limestone Crushing Plant wholesale Select 2024 high quality Limestone Crushing Plant products in best price from certified Chinese Crusher manufacturers, Cement Plant suppliers, wholesalers and factory on MadeinChina Crushing Degree: Coarse Crusher 1 / 6 Favorites Impact Crusher Limestone Stone Crusher Crushing Screening PF 2023年2月23日 Introduction An aggregate crushing plant is a machine that processes a wide range of raw materials into highquality aggregate, which is used in a variety of construction applications such as roads, buildings, and bridges Designing an efficient crushing plant is critical to achieving maximum productivity, profitability, and sustainability in the aggregates industryThe Ultimate Guide to Designing an Efficient Aggregate Crushing Plant2024年10月25日 K3 series Portable Crushing Plant uses modular vehicle design, able to be transported without disassembly Besides, it boasts rapid installation and production, safety and environmental protection The coarse crushing module adopts the vibrating feeder of larger specifications, equipped with doublelayer grate bars, with stronger feeding K3 Portable Crushing Plant Zenith Crusher2022年8月25日 The crushing characteristics of coarse aggregates for asphalt concrete were investigated under static and dynamic aggregate crushing value tests (ACVTs) The effect of various compaction loads was also examined by using a Marshall hammer, gyratory compactor and steel roller Six types of coarse aggregates were tested, including basalt aggregate, steel Crushing Characteristics of Coarse Aggregates for Asphalt

.jpg)

Crusher; Crushing; and Classification Equipment PPT

2020年11月8日 Mobile Impact Crusher / Impact Crushing Plants 51 Horizontal Shaft Impactors The Prisec™ crusher range can be configured to operate in application areas such as quarrying and recycling, in either primary or secondary crushing mode Sandvik’s patented design gives you amazing adaptability, ensuring you keep pace with everchanging