Process Of Coarse Aggregate

.jpg)

The movement property characterization of coarse aggregate

2022年12月26日 This study aims to analyze the effect of coarse aggregate on compaction dispersion and the movement behavior of coarse aggregate in the SGC test The motion trail 2024年7月1日 Coarse aggregate is the predominant component in concrete and represents the second most significant contributor to CO 2 emissions among raw materials used in concrete Machine learningguided optimization of coarse aggregate 2024年3月27日 The results show that the largest average speed in the mixing process was achieved with the spherical coarse aggregate Flat coarse aggregates have the highest (PDF) Numerical Study on the Effect of Coarse Aggregate 2024年2月29日 Natural coarse aggregate production process (Authors’) and better recycled aggregates with lesser attached mortar content The processing steps of natural coarse Production and Processing of Aggregates Springer

.jpg)

Effect of Coarse Aggregate Composition on Physical and

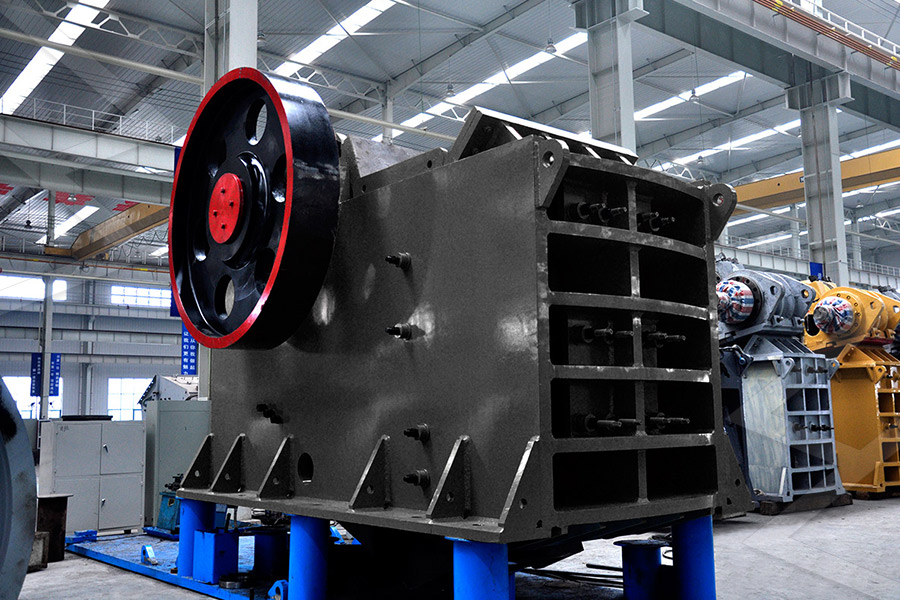

2019年8月10日 Specifically, the crushing process determines morphological characteristics of aggregates, and the chemical composition determines the physical and mechanical properties2021年11月22日 Construction aggregates derived from primary resources either by crushing of sound rock masses (crushed stone aggregates) or from naturally occurring unbound clastic Geomaterials as construction aggregates: a stateoftheart2023年12月22日 Important Raw Material—Coarse Aggregate Aggregate is a very crucial raw material for preparing concrete, especially coarse aggregate, which has a number of important Chapter 2 Important Raw Material Coarse Aggregate2022年6月21日 Highquality coarse aggregates are routinely used for the surface, base, and subbase layers in paved roads or the surface course in unpaved lowvolume roadsStabilization of Coarse Aggregates with

.jpg)

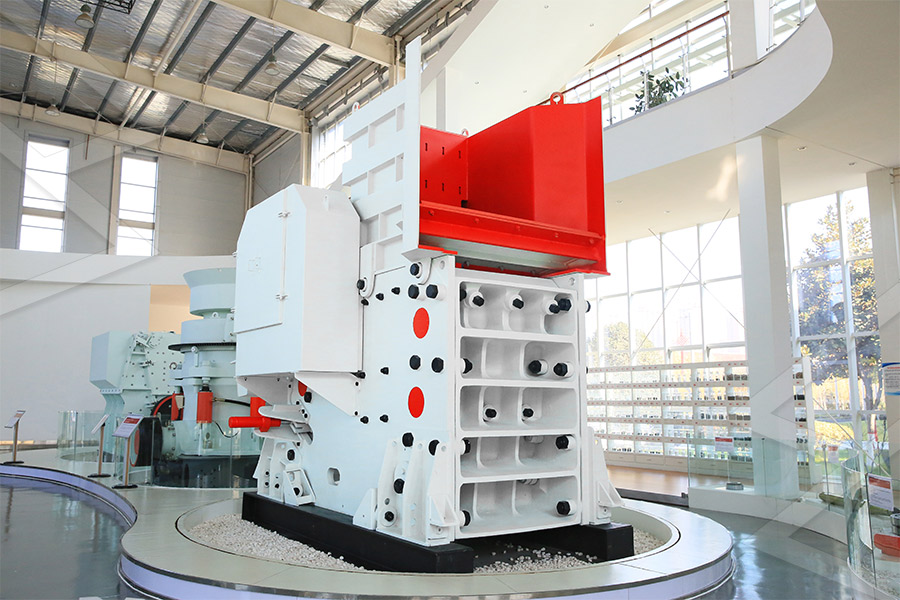

Coarse Aggregate: Types and Their Role in Construction

2024年8月29日 Coarse aggregate gives better water resistance and maintains dimensional stability in concrete It controls shrinkage and maintains balance in the heat retention during the curing process, which is crucial for cement hydration ; The coarse aggregate quantity determines the size and shape of the concrete mix The coarse aggregate also determines Coarse aggregate: Size: Fine gravel: 4mm – 8mm: Medium gravel: 8mm – 16mm: Coarse gravel: 16mm – 64mm: Cobbles: 64mm – 256mm: Boulders >256mm: Uses of Coarse Aggregates: They are also used in the preparation of breaking Coarse Aggregates: Types, Properites2023年9月2日 The modification method and the replacement rate of recycled coarse aggregate (RCA) have a great influence on the properties of recycled aggregate concrete (RAC) This paper aims to study the properties of RAC changes with the replacement rate and analyze the modification mechanism Composite impregnation treatment was carried out for RCA using Effect of Modification and Replacement Rate of Recycled Coarse 4 天之前 Manufacturing aggregate is a refined process that takes patience and time, but the results are well worth the effort Manufacturing aggregate – the process Aggregate is essentially a combination of mined materials broken down into The Process of Manufacturing Aggregate KB Crushers

Coarse Aggregate — Material Testing Expert

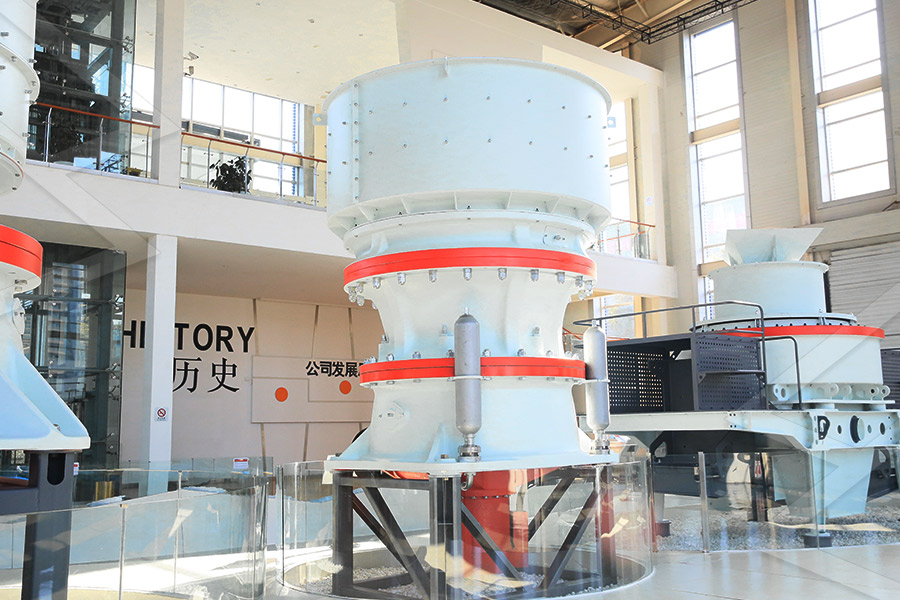

2023年8月14日 Decoding Coarse Aggregates: Origins and Production Coarse aggregates are granular materials, typically larger than 475 millimeters, sourced from diverse reserves like crushed stone, gravel, and sand The intricate production process involves: Extraction: Raw materials are sourced from quarries, mines, or natural deposits rich in aggregates2024年6月11日 Figure 7 depicts the slump values of concrete with varying proportions of recycled coarse aggregate in the manufacturing process The designated value for the reference samples was 120 mm The slump test findings for concrete containing recycled coarse aggregate particles demonstrated a reduction in the workability of the mixes as the quantity Studying the usability of recycled aggregate to produce new 2024年6月13日 Understanding ASTM C136 is essential for anyone involved in the construction industry This standard for sieve analysis judges the particle size distribution of fine and coarse aggregates, critical for maintaining building material standards Our article breaks down the nuts and bolts of the test method, discusses its pivotal role in quality control, and outlines the ASTM C136: Fine and Coarse Aggregate Sieve Analysis2024年7月29日 In this paper, uniaxial compression tests were carried out on nine concrete specimens with different coarse aggregate particle size ranges in single and continuous gradation at curing ages of 3, 7 and 28 d, respectively The acoustic emission (AE) and microseismic (MS) signals of the whole loading process were monitored by combining AE and MS to investigate Effect of Coarse Aggregate Gradation on the Acoustic

.jpg)

Effect of Coarse Aggregate Size and Grouting Process on

2019年3月26日 desired flowability and strength was used to produce PAC by both pumping and gravity process Four different sizes of coarse aggregates were considered ie 45mm, 37 mm, 20 mm and 14 mm Variation in compressive strength against coarse aggregate size and grouting process was evaluated Excess voidage and resistance to chloride ion penetration was2024年4月30日 Coarse aggregate plays a crucial role in the production of concrete, offering both economic and technical advantages over cement [1,2,3] It is a costeffective component that helps to reduce the overall cost of concrete production Throughout the casting process, a table vibrator was used to impart a mechanical tremor to the cylinders Exploring the Potential of Pumice Stone as Coarse Aggregate2024年2月27日 Natural coarse aggregate production process (Authors’) Full size image 4 Closure Waste generated from the demolition of existing structure is the major source of C D waste Simply dumping this waste in landfill will create serious impact on social, economic, and environment life cycle A detailed process to extract valuable and reusable Production and Processing of Aggregates SpringerLink2023年8月3日 41 CoarseGrained Aggregates The use of singlesized aggregates in concrete results in more voids, but it provides excellent resistance against sudden impact On the other hand, graded aggregates contain Grading of Aggregates: Their Significance, Types

.jpg)

E107fm American Concrete Institute

2017年8月5日 %PDF16 %âãÏÓ 165 0 obj > endobj xref 165 24 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n Coarse Aggregate is an important material to create concrete In internal reinforcements the space between TMT Bars should be smaller This will allow the aggregate to pass between the rebar and settle evenly throughout the structure Needless to say, the selection of these aggregates is a very important process Size of Coarse AggregateCoarse Aggregate in Concrete Construction Shyam Steel2022年9月2日 The reuse of construction and demolition waste has become vitally important because of the requirements of environmental protection and sustainable development The vibration mixing process is a new technology and novel method that improves the performance of concrete by optimizing the mixing process without changing constituents This study discusses Preparation of Recycled and MultiRecycled Coarse 2018年10月1日 Aggregate image measurement system (AIMS) was used to measure and analyze the angularity, texture, sphericity and flatness and elongation (FE) characteristic of recycled and natural coarse aggregate [45]Fig 3a, b, c and d show the morphological characteristics of recycled and natural coarse aggregateAngularity is related to the gradient Properties of recycled aggregate concrete prepared with scattering

.jpg)

(PDF) Numerical Study on the Effect of Coarse Aggregate

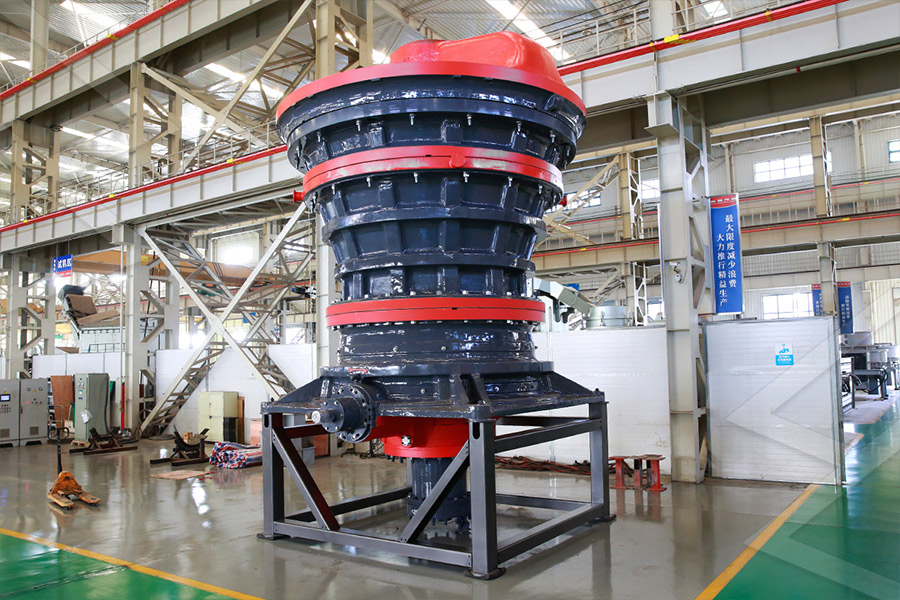

2024年3月27日 The shape of coarse aggregate is an important factor determining the performance of concrete, and it also affects the whole mixing process This article selected four typical coarse aggregates and 2022年4月25日 Dam concrete contains very large aggregates, and the influence of coarse aggregate size on AARinduced deterioration requires a deep understanding In this paper, a mesoscale particle model of concrete was presented to simulate the AAR process and mechanical testing of AARaffected concreteInfluence of coarse aggregate size on deterioration of 2020年9月29日 Preplaced concrete (PAC) is a simple perception; it is made using the same basic elements as traditional concrete: cement, coarse aggregate, sand and water as well as chemical admixturesEffect of Coarse Aggregate Arrangement and Grouting Process 5 天之前 Read More: Aggregate Testing 7 Test On Aggregates Coarse Aggregate Test Aggregate Crushing Value Test Result For accurate test results conduct the test at least 3 times and take an average of 3 values Aggregate Crushing Value Test Lab Report Aggregate Crushing Value Limits for Road PavementAggregate Crushing Value Test Procedure, Result

A Comprehensive Review on Recycled Aggregate and Recycled Aggregate

2021年8月1日 Since the size of a coarse aggregate particle (usually 10 – 20 mm in diameter) is several orders of magnitude larger than that of the cement grains Recycled mixed aggregate requires less separation process from CDW than other RAs, eg recycled concrete aggregate In the viewpoint of reducing energy consumption and emission of harmful The coarse aggregate specific gravity test measures coarse aggregate weight under three different sample conditions: Ovendry (no water in sample) Superpave mix design is a volumetric process; it relies on mixing constituent materials on the basis of their volume However, aggregate and asphalt binder volumes are diffucult to measure Coarse Aggregate Specific Gravity Pavement Interactive1 天前 Aggregate crushing is the process of breaking down the large pieces into smaller particles Screening – different sized aggregates are required for different types of construction projects and materials – thus they need separating An Essential Guide To Construction Aggregates2023年8月15日 Jahan and Sangitha (2021) [19] have studied on partial replacement of coarse aggregate by Expanded Polystyrene Beads (EPS) in concrete and concluded that increase in the EPS beads content in concrete mixes reduces the compressive, tensile strength of concrete and also improves the workability with increase in EPS content Very little research has been done A comparative study on partial replacement of coarse

Property Improvement of Recycled Coarse Aggregate by

2023年3月9日 Recycled aggregate (RA) made from waste concrete has inferior fundamental properties, ie, apparent density, water absorption, mass variation, carbonation ratio, etc, compared to those of natural aggregate (NA), severely restricting its application in practical projects However, using CO2 to accelerate RA carbonation can effectively improve these 2013年3月26日 T27T11short12 Aggregate 121 Pub October 2012 SIEVE ANALYSIS OF FINE AND COARSE AGGREGATES FOP FOR AASHTO T 27 MATERIALS FINER THAN 75 µm (No 200) SIEVE IN MINERAL AGGREGATE BY WASHING FOP FOR AASHTO T 11 Scope Sieve analysis determines the gradation or distribution of aggregate particle sizes within a SIEVE ANALYSIS OF FINE AND COARSE AGGREGATES2024年3月27日 The shape of coarse aggregate is an important factor determining the performance of concrete, and it also affects the whole mixing process This article selected four typical coarse aggregates and simulated the motion behavior of the coarse aggregate and mortar in a dual horizontal axis mixer using discrete element software, EDEM The mixing motion of Numerical Study on the Effect of Coarse Aggregate Shape 2024年7月1日 The future studies can incorporate cost calculations for the carbonation process of coarse aggregate to provide a more comprehensive evaluation of all types of coarse aggregates Additionally, as the investigation on the carbonation of RCA advances, it will be feasible to a broader range of properties in prediction and optimization analysis Machine learningguided optimization of coarse aggregate

.jpg)

Impact of coarse aggregate morphology andseparation

2024年7月15日 The coarse aggregate morphological characteristics greatly influence concrete performance These characteristics are typically assessed based on the angularity, shape, and surface texture of coarse aggregates [[19], [20], [21], [22]]Current methods for evaluating morphological characteristics of aggregates encompass analysis of twodimensional (2D) 2014年6月11日 The volume fraction of the coarse aggregate in the conventional plastic concrete is controlled relatively low to ensure a required workability In this paper, a new type of coarse aggregate interlocking concrete with strength ranging from C30 to C80 was prepared with scatteringfilling aggregate process The strength of concrete prepared with this method Low Carbon Concrete Prepared with ScatteringFilling Coarse Aggregate 2021年7月8日 In another word; aggregates retained on a 475 mm sieve are coarse aggregate Coarse aggregate provides the volume to the concrete It is used as a filler material in concrete, roads, etc 2 Origin of Coarse Aggregate Coarse Aggregate Classification of Coarse 2019年4月1日 PreplacedAggregate Concrete (PAC) is a type of preplaced concrete where coarse aggregate is placed in the mold and a Portland cementsand grout with admixtures is injected to fill the voidsEffect of Coarse Aggregate Size and Grouting Process on

Recycled Aggregate Concrete (RAC)

2022年11月15日 It also reduces Carbon Dioxide emission by 23%28% as the cement can also be retrieved from the recycling process Therefore the emission of CO2 in the production of new cement is less than before Here the 2022年9月15日 The properties of 3DPC were compared with cast concrete to explore the effect of the extrusion process on the coarse aggregate distribution and microstructure formation of 3DPC, aiming to reveal the evolution mechanism of mechanical properties and interlayer bonding properties of different printed samples The results of this investigation can Optimization of 3D printing concrete with coarse aggregate 2022年12月26日 The process of coarse aggregate movement test during compaction 24 Data processing method Threedimensional (3D) reconstruction of specimens in different compaction stages and corresponding CT scanning were performed, and VG STUDIO MAX 30 was employed to obtain and track the spatial dynamic changes and fragmentation of aggregates The movement property characterization of coarse aggregate 2023年11月14日 Since the construction industry is one of the major sectors responsible for the overexploitation of natural resources and the production of greenhouse gases, there is an urgent need to adopt a sustainable and environmental friendly approach to mitigate climate degradation Research has explored the potential of recycled aggregate (RA) as a viable alternative to Development of lowcarbon recycled aggregate concrete

Effect of Coarse Aggregate Grading on Mechanical

2023年7月27日 This work presents a discussion of the basic properties of broken mineral limestone aggregates with the specification of the properties affecting the fracture toughness of concretes made with these aggregates To determine the influence of the grainsize distribution of coarse aggregates for each concrete series, two types of aggregate grain were used, with 2023年10月24日 The use of recycled coarse aggregate as a partial replacement for natural coarse aggregate from Kulon Progo reduces the properties of hardened concrete by up to 15% source and the construction site or concrete mixing plant is a vital consideration in the selection process utilization of natural coarse aggregate In the Yogyakarta region Influence of mixed recycled coarse aggregate on the 2023年11月20日 This process is followed by an abrasion process called the hybrid process (HP) Coarse aggregate specific gravity and water absorption percentage—IS 2386 (Part III) ASTM: C127 [57, 58] Los Angeles abrasion test for abrasion resistance of coarse aggregate—IS 383, IS 2386 (Part IV) ASTM: D5821 [59, 60]Influence of Pretreatment Methods for Coarse Recycled 2023年11月13日 The differences in physical properties, chemical properties, and mechanical properties between reclaimed concrete aggregate and natural aggregate are discussed in this paper In this paper, the commonly used improvement techniques of recycled concrete aggregate are reviewed Physical modification involves peeling the attached mortar layer using Modification of Recycled Concrete Aggregate and Its Use in