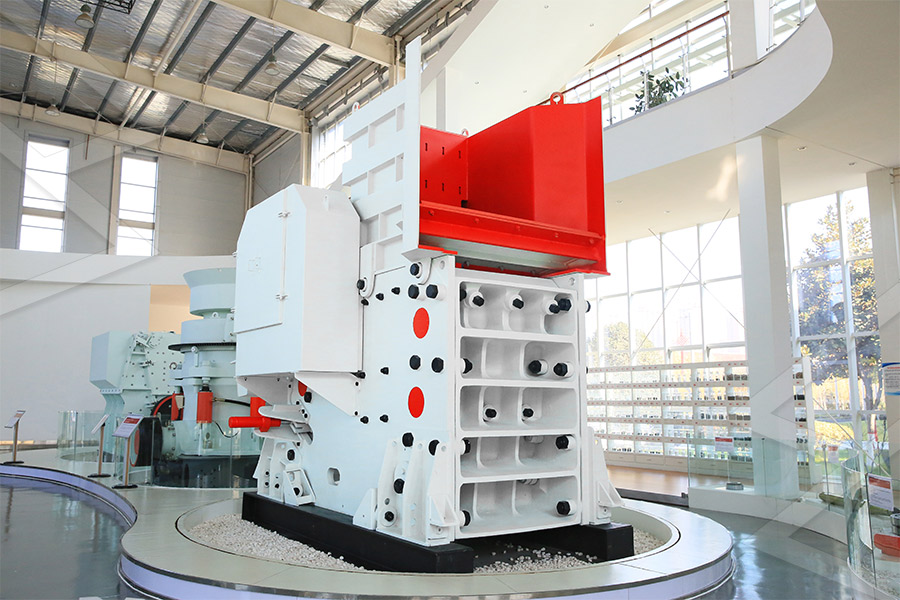

Diagram Of Gyratory Mining Mill With Measurements

.jpg)

Gyratory and Cone Crusher ScienceDirect

2016年1月1日 Detail descriptions of designs are given of large gyratory crushers that are used as primary crushers to reduce the size of large runofmine ore pieces to acceptable sizes 2004年11月1日 Wear measurements were taken for inservice crushers during the research period using a novel laser profile measurement device Data from the wear measurements Liner wear and performance investigation of primary gyratory crushers 2021年6月24日 METSO’S MINING AND CONSTRUCTION TECHNOLOGY Metso’s Mining and Construction Technology in brief To be successful in today’s quarry and sand and gravel Crushing and Screening Handbook AusIMM2023年10月30日 This study developed a digital sensor and a discrete element modelling (DEM)coupled methodology to monitor and reconstruct the gyratory crusher concave liner wear pattern The developed digital sensor was able to Modelling of Gyratory Crusher Liner Wear Using

.jpg)

Torque Analysis of a Gyratory Crusher with the

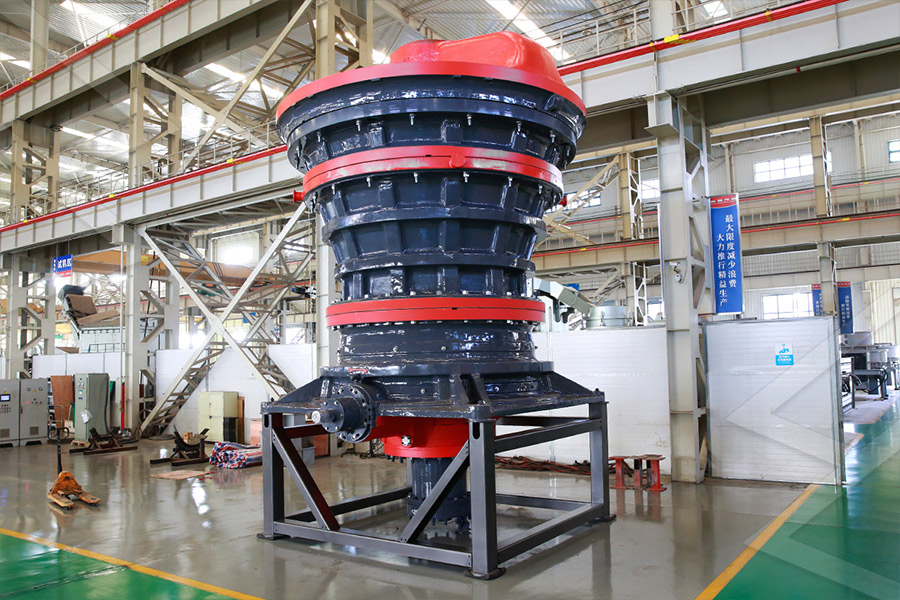

2021年8月13日 In this paper, a DEM model was applied to a copper mining gyratory crusher to perform a comprehensive analysis of the loads in the mantle, the crushing torque, and crushing power A novel polar representation of the 2024年1月1日 Gyratory crusher is a crushing equipment that uses the gyratory motion of the crushing cone in the conical cavity inside the shell to extrude, bend, and impact materials, for Gyratory Crusher SpringerLink2022年12月28日 capacity mining installations Superior™ MKIII is the first high speed Gyratory The new features allow significant CAPEX reduction of a primary crushing stage from the Mining crushers SuperiorTM MKIII Primary GyratoryCrushers are essential machines in several industries for particle size reduction They are invaluable in laboratories (higher institutions and research centres), the mining and construction3 A typical Gyratory crusher (Source:

AMIT 135: Lesson 5 Crushing – Mining Mill

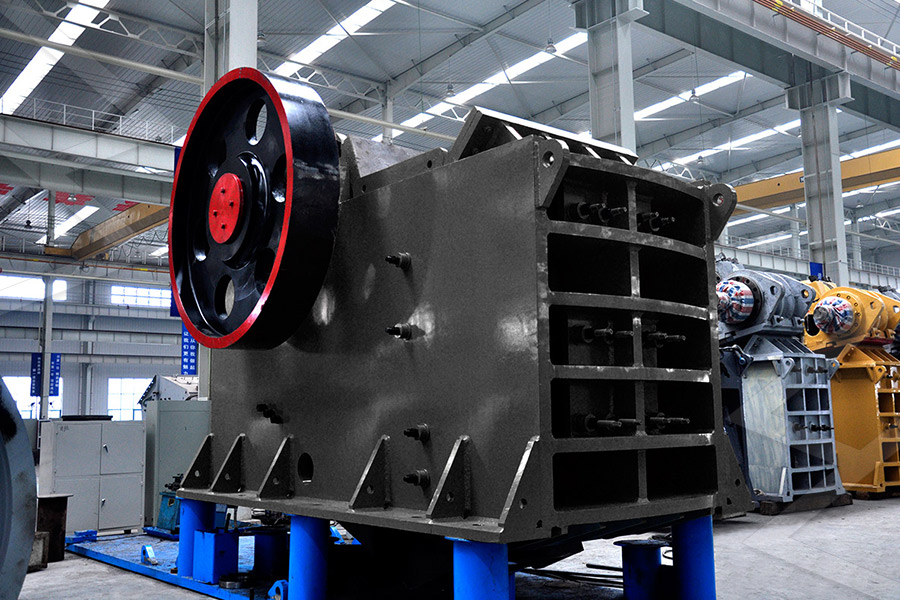

Diagram of a gyratory crusher [image: 135516)] Gyratory Crushing Action Designs of the breaking faces vary with manufacturer As a result, the product size distribution varies When the feed drops into the crusher, the mantle Gyratory crushers are principally used in surfacecrushing plants The gyratory crusher (Figure 65) consists essentially of a long spindle, carrying a hard steel conical grinding element, the head, seated in an eccentric sleeveThe spindle is suspended from a “spider” and, as it rotates, normally between 85 and 150 rpm, it sweeps out a conical path within the fixed crushing Gyratory Crusher an overview ScienceDirect Topics2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for Crushing in Mineral Processing 911MetallurgistThis is typically achieved in several stages of a detailed and professional mining operation and/or gyratory crushers are usually employed a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when Jaw Crusher Explained saVRee

.jpg)

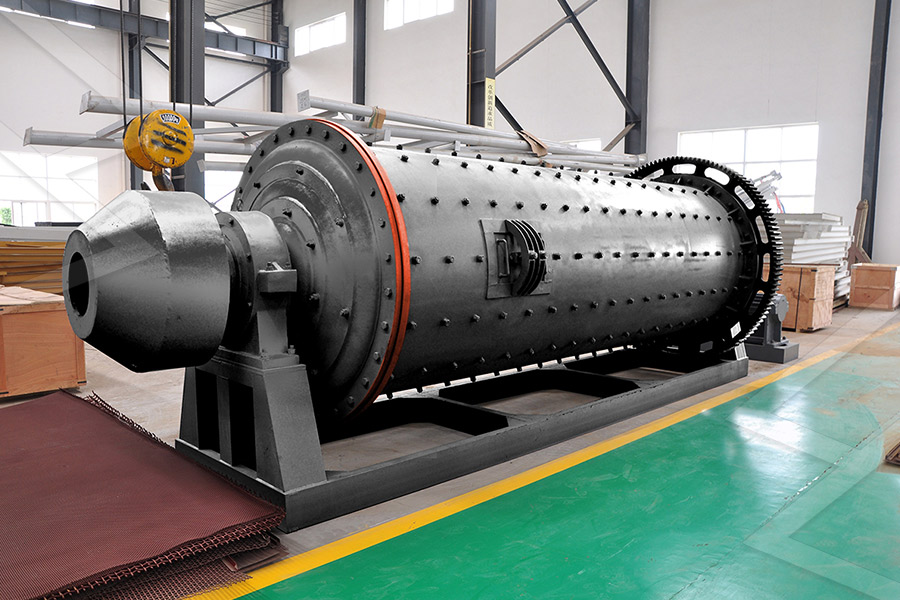

Rod Mills: Efficient Grinding Solutions for Mining

2016年6月1日 The pulp discharge from the mill is collected by a housing around the discharge ring and may be directed to either side of the mill or immediately below the mill centerline Dry ROD MILL Grinding No other type of mill is so well adapted to dry grinding materials to 4 or 8 mesh in single pass with the production of a minimum amount of fines2021年1月12日 MEASUREMENT OF MILL FEED SIZE Particle size measurements are made at key locations between the mine and the mill using the WipFrag image analysis system from WipWare Inc A description of the system and how it works is given elsewhere (Maerz 1996) Installation Cameras were installed on all five grinding line feed conveyors, as wellThe Importance of Primary Crushing in Mill Feed Size AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill Because of the range of mill sizes available, AG/SAG milling can often be accomplished with fewer lines than in a conventional rod mill/ball mill circuit A diagram of types of AG/SAG AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator 2018年12月26日 Gyratory Crushers Gyratory crusher is generally used as a primary crusher The crusher is popular due to its high throughput capacity and the large sized opening The crusher is well suited for handling direct feed from haul/dump trucks The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strengthConstruction, Working and Maintenance of Practical

.jpg)

Crushing Plant Design and Layout Considerations 911

2024年9月24日 stock and provide spare parts close to the mining operation Good geotechnical information is essential to crushing plant siting and design Installing a primary crushing plant on solid rock reduces the cost of concrete and structural steel Life of Mine/Expansion Plans The life of the mine is a key element in the design of any crushing plant2021年4月19日 Published in MATERIA 2021;23:6366 The idea of minetomill optimization has been tested in various mines in last decades, resulting in higher mill throughput in many mines, but also (PDF) Feasibility and necessity of mine to mill ResearchGateGyratory crushers Run of mine material is transferred into a gyratory crusher’s upperlevel hopper The walls of the gyratory crusher’s hopper are lined with “Vshaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a cone Impactor and hammer mill diagrams Tertiary crushing equipment and beyondTypes of Crushers: What You Need to Know Machinery 2023年2月28日 Gyratory cone crushers are powerful machines that have revolutionized the crushing industry Their unique design and superior performance make them a popular choice for a wide range of applications, Unveiling the Advantages and Applications of

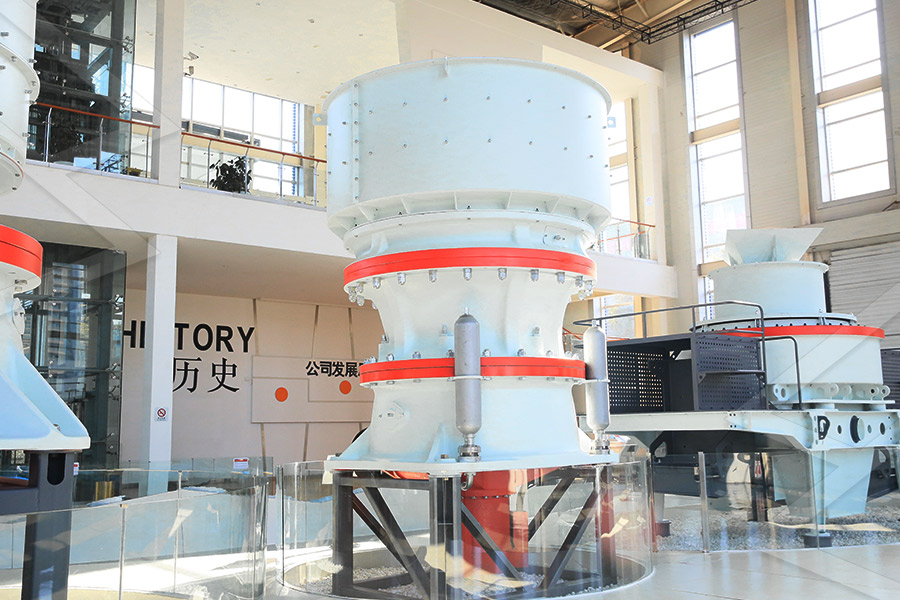

Principle of a cone or gyratory crusher

Download scientific diagram Principle of a cone or gyratory crusher from publication: Cone Crusher Performance PhD Thesis Cone crushers are used by both the aggregate producing and the mining Crushers are needed in a lot of industries for the sole purpose of size reduction They are invaluable machines in laboratories (whether for institutions, government or private owned), mining and 3 A typical Gyratory crusher (Source:2017年4月18日 Figure 51 Schematic diagram of a crusher showingg the open and closedside settings 51 Jaw and Gyratory Crushers Jaw and gyratory crushers are used mostly for primary crushing They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material The capacity of the crusher is determined by its sizeTECHNICAL NOTES 5 CRUSHERS 911 Metallurgist2018年12月26日 Gyratory Crushers Gyratory crusher is generally used as a primary crusher The crusher is popular due to its high throughput capacity and the large sized opening The crusher is well suited for handling direct feed from haul/dump trucks The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strengthConstruction, Working and Maintenance of Practical

.jpg)

Full MinetoMill Optimization Continuous Improvement

2023年10月16日 Chapada's open pit coppergold mine and processing plant commenced operation in 2007 As mining has progressed deeper the ore hardness has increased, adversely impacting plant throughput2023年3月22日 employing steel materials such as hammers mill has revolutionize the processing of minerals in a small scale and large scale capacity There are various types of machines generally used for size reduction of materials These are Gyratory crusher Jaw crusher, Ball mill, Burr mill and many others Thus, of all the crushingDESIGN, FABRICATION AND TESTING OF A 2021年8月13日 Comminution by gyratory crusher is the first stage in the size reduction operation in mineral processing In the copper industry, these machines are widely utilized, and their reliability has become a relevant aspect To optimize the design and to improve the availability of gyratory crushers, it is necessary to calculate their power and torque accurately The discrete Torque Analysis of a Gyratory Crusher with the Discrete Element 2024年4月19日 The mantle is rotating and the material is getting compressed against the concave surface thereby it breaks and becomes smaller Gyratory crushers are valued for their high capacity, continuous operation, and ability to process feeds up to 1500 mm in diameter Unlike jaw crushers, gyratory crushers generally have higher reduction ratiosTypes of Crushers Explained: Everything You Need to Know

2 GYRATORY CRUSHERS 911 Metallurgist

2017年4月19日 Over the years the gyratory crusher has developad into a number of forms Essentially the surviving form of gyratory crusher which is used throughout the mining industry today is the hydraulically supported shortshaft crusher Occasionally some plant operators will order the older spidersuspended shortshaft gyratory crusher TheBall Mill Introduction There are three main stages to mineral processing in the mining industryThese are: Comminution (crushing and grinding); Beneficiation (separation and concentration); Smelting and refining; Ball mills are Ball Mill (Ball Mills Explained) saVRee saVRee2022年1月1日 Schematic diagrams of jaw and gyratory crushers (Courtesy of Metso) measure 4 m wide x 11 m long and weigh more than 100 tons each IsaMill operations started in 1994 at the Mount Isa Mines Lead/Zinc Concentrator and then at MIM’s McArthur River Mine in 1995 These mills have been used to liberate sphalerite and galena at Mount Isa Comminution and classification technologies of iron ore2006年10月9日 Tsakalakis, KG, 1990, Product Size Distributions of Industrial Gyratory Crushers, Mining and Metallurgical Annals, Vol 75, pp4148, (in Greek with English abstract) Mineral Processing Modelling the crushingsizing procedure of

Gyratory VS Jaw Crushers: Advantages Disadvantages

2016年2月28日 Then superimpose the diagram of the jaw crusher opening, laying it in tangent to the head circle To facilitate this work for the line of Superior McCully gyratory crushers, we list in the following table the top diameters of the heads, and openings between head and concaves for straightface, and nonchoking, concavesThese measurements are immensely useful but could be expensive and time consuming It is important to be prudent on representative sample selection with a clear purpose which served the industry until 2001 Typical gyratory crusher capacities are 350–10,000 tph, known for their high capacity and low main tenance MinetoMill is an Physical Processing: Innovations in Mineral Processing2020年1月16日 Buzwagi Gold Mine (BGM) is operated by Acacia Mining and located in the Lake Victoria Goldfields of central Tanzania The mine commenced its operation since April 2009 and treats a sulphide copper (PDF) Optimization and performance of grinding circuits: the 2004年11月1日 The research was aimed at understanding gyratory crusher liner wear in the overall context of the crushing process Wear measurements were taken for inservice crushers during the research period using a novel laser profile measurement device The flow of material from mine to mill involves blasting, loading, hauling, crushing, milling and Liner wear and performance investigation of primary gyratory crushers

.jpg)

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 on mill dimensions, the type of the mill (overflow or grate discharge), the speed of rotation, the mill loading, the final product size required from a given feed size2024年4月28日 Explore the anatomy of a ball mill with a detailed ball mill diagram Learn more on our blog for valuable insights into this essential industrial equipment Equipment Alongside the mining industry, ball mills are also used in different sectors, such as cement production, for grinding clinker and other raw materials; ceramic manufacturing Exploring Ball Mill Diagram: A Comprehensive Guide JXSC2018年1月1日 To provide the mining enterprises of Kazakhstan with a new type of mill, which has a reduced power consumption Mining mills are the main consumers of electricity in the mining sector, so the task Design of the centrifugalgyratory mill of mining production2023年10月30日 A gyratory crusher is a key mineral processing asset in a comminution circuit Monitoring and predicting the crusher liner wear is essential to ensure the throughput and product quality are maintained during Modelling of Gyratory Crusher Liner Wear Using

Compare Gyratory Crusher vs Jaw Crusher

2015年7月18日 To accomplish this reduction in size takes several steps or stages of crushing and grinding Primary crushing is the first of these stages Generally speaking there are two types of primary crushers, lets compare schematic diagram of gyratory crusher – Crusher gyratory crusher diagram india, mining equipment 6 Jaw Gyratory Crusher Workingyratory crusher working principle and diagram Grinding Mill Download scientific diagram — Gyratory crusher (adapted from ThyssenKrupp, 2005) As of 2010, in the world mining industry, about 200 large mills of full or partial SAG were in operation Gyratory crusher (adapted from ThyssenKrupp, 2005)T14:02:06+00:00 2 GYRATORY CRUSHERS At the time these early gyratory crushers were developed all mining and quarrying, either underground or open pit, was done veyon transporting crushed material to the mill had limited capacity per hour factured by AllisChalmers features a 360D circular rim with the twoAllis Chalmers Manufacturers, Factory, Diagram Parts Of Gyratory Mining Mill Allis Chalmers ssshk

Grinding mills for mining and minerals processing Metso

Our Metso Premier™ mills and Select™ mills are supported by our comprehensive services network to ensure optimization during your mills lifetime Also the Premier™ mills and Select™ mills come ready to be easily integrated with our mill reline equipment and full mining portfolio providing a onestopshop for your minerals processing needs!2020年10月1日 The gyratory crusher is widely used in primary crushing of metal ore such as iron ore and copper ore due to its high productivity and large feed inlet [[1], [2], [3]]In recent years, with the growth of the world's population, the development of urbanization and the improvement of living standards, the demand for the ore continues to increase, therefore, the Simulation and optimization of gyratory crusher 2021年8月11日 to the discrete element method, model based control, plantwide and minetomill optimization, and machine learning applications for data acquisition and process optimization 1 Introduction Rocks, ores, and their subproducts have always been of great importance for civilization For example, as mentioned in De Re MetalA review of modeling and control strategies for cone A mining primary jaw gyratory crusher for large, coarse materials The main benefit of the Jaw Gyratory Crusher Pro is its ability to crush bigger chunks of material at high throughput rates – without succumbing to blockages and bridging What’s more, maintenance is easy by design, so you can keep downtime to a minimumJaw Gyratory Crusher Pro FLSmidth

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Mill Type Overview Three types of mill design are common The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 – 250 microns; The CenterPeriphery Discharge mill has feed reporting from both ends and the product